Die Casting

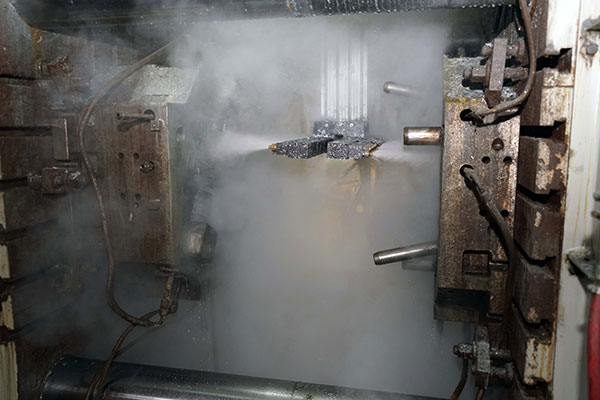

Alumina uses different alloys in order to satisfy customer requirements with a daily melting capacity of 86 tons. The most used alloys are EN AC 46000 (GDAlSi9Cu3), EN AC 44300 (GDAlSi12) and EN AC 47100 (GDAlSi13Fe) Alumina foundry consist of fully automated die casting cells including trimming. Every shot parameters are automatically controlled and recorded during project lifetime. All machines are connected to our ERP system which gave the opportunity to track OEE online. Alumina invest the right die casting cell configurations according to customer project requirements till 2500T. Protect the environment is our core value so Alumina made all necessary investments. All die casting cells are equipped with KMA air filtration units. Also all residual oils collected from machines are filtrated in our central oil treatment center.